Pakupanga ndi kupanga ma laser amphamvu kwambiri a semiconductor, ma laser diode bar amagwira ntchito ngati mayunitsi otulutsa kuwala. Kugwira ntchito kwawo sikudalira kokha mtundu wa tchipisi ta laser komanso kwambiri pa njira yopakira. Pakati pa zinthu zosiyanasiyana zomwe zimaphatikizidwa pakupakidwa, zinthu zosungunulira zimagwira ntchito yofunika kwambiri monga kulumikizana kwa kutentha ndi magetsi pakati pa chip ndi chotenthetsera.

1. Udindo wa Solder mu Laser Diode Bars

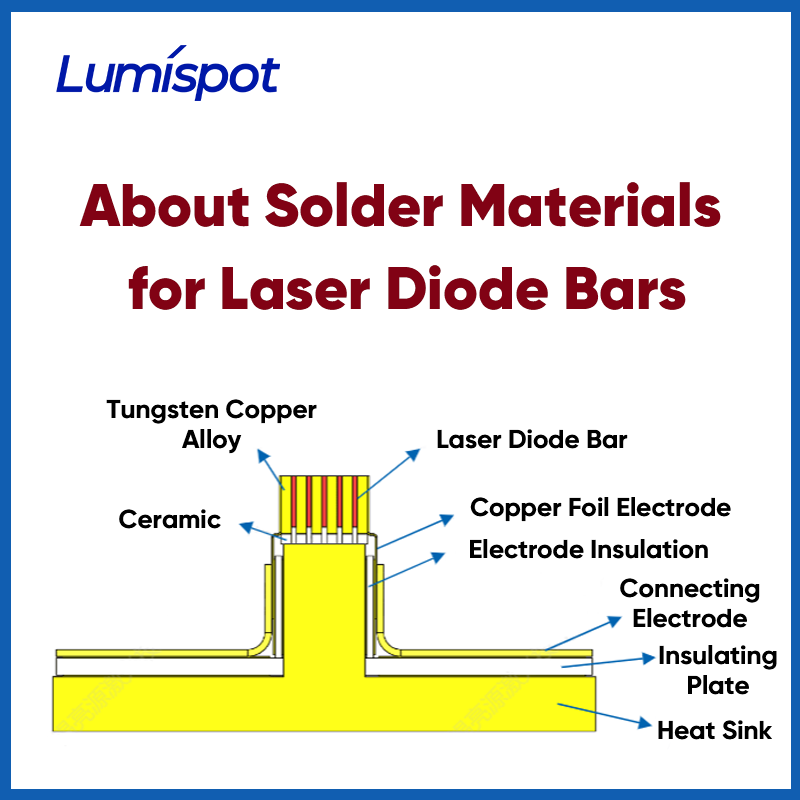

Mipiringidzo ya laser diode nthawi zambiri imaphatikiza ma emitter angapo, zomwe zimapangitsa kuti pakhale mphamvu zambiri komanso kufunikira kosamalira kutentha kwambiri. Kuti kutentha kuthe bwino komanso kukhazikika kwa kapangidwe kake, zinthu zosokedwa ziyenera kukwaniritsa izi:

① Kutentha kwambiri:

Zimathandiza kuti kutentha kuchoke pa laser chip kuyende bwino.

② Kunyowa bwino:

Amapereka mgwirizano wolimba pakati pa chip ndi substrate.

③ Malo oyenera osungunula:

Zimaletsa kubwereranso kapena kuwonongeka panthawi yokonza kapena kugwira ntchito pambuyo pake.

④ Kuchuluka kwa kutentha komwe kumagwirizana (CTE):

Amachepetsa kutentha kwa chip.

⑤ Kukana kutopa kwambiri:

Imawonjezera moyo wa chipangizocho.

2. Mitundu Yodziwika ya Solder ya Laser Bar Packaging

Nazi mitundu itatu ikuluikulu ya zinthu zosungunulira zomwe zimagwiritsidwa ntchito kwambiri poika mipiringidzo ya laser diode:

①Aloyi wa Golide-Tin (AuSn)

Katundu:

Kapangidwe ka Eutectic ka 80Au/20Sn ndi malo osungunuka a 280°C; kutentha kwambiri komanso mphamvu ya makina.

Ubwino:

Kukhazikika bwino kwambiri kutentha, kutopa kwa nthawi yayitali kutentha, kopanda kuipitsidwa ndi zinthu zachilengedwe, komanso kudalirika kwambiri

Mapulogalamu:

Makina ankhondo, ndege, ndi makina apamwamba a laser a mafakitale.

②Indium Yoyera (Mu)

Katundu:

Kutentha kosungunuka kwa 157°C; kofewa komanso kosavuta kusungunuka.

Ubwino:

Kuchita bwino kwambiri poyendetsa kutentha, kupsinjika pang'ono pa chip, koyenera kuteteza nyumba zosalimba, koyenera kulumikiza kotsika kutentha

Zoletsa:

Imakhala ndi okosijeni; imafuna mpweya wopanda mpweya panthawi yokonza, mphamvu yochepa ya makina; si yoyenera kugwiritsidwa ntchito ndi katundu wambiri

③Makina Ogulitsa Ophatikizana (monga, AuSn + In)

Kapangidwe:

Kawirikawiri, AuSn imagwiritsidwa ntchito pansi pa chip kuti ikhale yolimba, pomwe In imagwiritsidwa ntchito pamwamba kuti iwonjezere kutentha.

Ubwino:

Zimaphatikiza kudalirika kwambiri ndi kuchepetsa kupsinjika, zimapangitsa kuti ma phukusi azikhala olimba, komanso zimagwirizana bwino ndi malo osiyanasiyana ogwirira ntchito.

3. Zotsatira za Ubwino wa Solder pa Magwiridwe Abwino a Chipangizo

Kusankha zinthu zogulitsidwa ndi kuwongolera njira kumakhudza kwambiri magwiridwe antchito amagetsi ndi kukhazikika kwa nthawi yayitali kwa zida za laser:

| Chinthu Chogulitsa | Zotsatira pa Chipangizo |

| Kufanana kwa gawo la solder | Zimakhudza kugawa kutentha ndi kusinthasintha kwa mphamvu ya kuwala |

| Chiŵerengero chopanda kanthu | Malo opanda kanthu ambiri amachititsa kuti kutentha kukhale kolimba komanso kutentha kwambiri m'malo enaake |

| Ukhondo wa aloyi | Zimayambitsa kukhazikika kwa kusungunuka ndi kufalikira kwapakati pa zitsulo |

| Kunyowa kwa nkhope | Imazindikira mphamvu yolumikizirana ndi mawonekedwe a kutentha kwa mawonekedwe |

Pogwiritsa ntchito mphamvu zambiri mosalekeza, ngakhale zolakwika zazing'ono pakusokedwa kwa soldering zimatha kubweretsa kutentha kwambiri, zomwe zimapangitsa kuti magwiridwe antchito awonongeke kapena kulephera kwa chipangizocho. Chifukwa chake, kusankha solder yapamwamba kwambiri ndikugwiritsa ntchito njira zolondola zosokedwa ndizofunikira kwambiri kuti pakhale kulongedza kwa laser kodalirika kwambiri.

4. Zochitika ndi Chitukuko cha Mtsogolo

Pamene ukadaulo wa laser ukupitilira kulowa mu mafakitale, opaleshoni yachipatala, LiDAR, ndi madera ena, zipangizo zosokera zopangira ma laser zikusintha motere:

①Kusokera kotentha pang'ono:

Kuti iphatikizidwe ndi zinthu zomwe zimakhudzidwa ndi kutentha

②Chotsukira chopanda lead:

Kukwaniritsa RoHS ndi malamulo ena okhudza chilengedwe

③Zipangizo zolumikizira kutentha kwambiri (TIM):

Kuti muchepetse kukana kutentha

④Ukadaulo wa micro-soldering:

Kuthandizira miniaturization ndi kuphatikiza kwakukulu

5. Mapeto

Ngakhale kuti ndi zazing'ono, zinthu zosokera ndi zofunika kwambiri polumikizira zomwe zimatsimikizira kuti zipangizo za laser zamphamvu kwambiri zikugwira ntchito bwino komanso kudalirika. Mu phukusi la mipiringidzo ya laser diode, kusankha solder yoyenera ndikuwongolera njira yolumikizira ndikofunikira kuti pakhale ntchito yokhazikika kwa nthawi yayitali.

6. Zambiri Zokhudza Ife

Lumispot yadzipereka kupatsa makasitomala zida za laser zodalirika komanso zodalirika komanso njira zopakira. Popeza tili ndi chidziwitso chambiri pakusankha zinthu zosokera, kapangidwe ka kayendetsedwe ka kutentha, komanso kuwunika kudalirika, tikukhulupirira kuti kukonzedwa kulikonse mwatsatanetsatane kumatsegula njira yopita ku luso labwino. Kuti mudziwe zambiri zaukadaulo wamakina opangira laser amphamvu kwambiri, omasuka kulumikizana nafe.

Nthawi yotumizira: Julayi-07-2025